Biogas / Biomethane compressor

Biogas recycling to biomethane and using for vehicle refueling

Starting position / boundary conditions

Biogas is gaining importance as an environmentally friendly alternative energy form. Especially interesting is the reprocessing into biomethane to be delivered to the natural gas grid or to be used for example by the vehicle refueling.

In this reference example, our client is a biogas upgrading plant constructor in Switzerland. This is a pilot project for a decentralized and independent gas supplies. The project is funded by the Federal Office of Energy and by the Natural Gas Industry.

Requirements

The biogas comes from a sewage treatment plant. The compression was preconditioned before - the moisture and H2S content had to be reduced. The CO2 in the biogas is separated from the methane by a membrane. The biogas is compressed oil-free in two stages.

The compression to a maximum of 300 bar for vehicle refueling is performed in the second step.

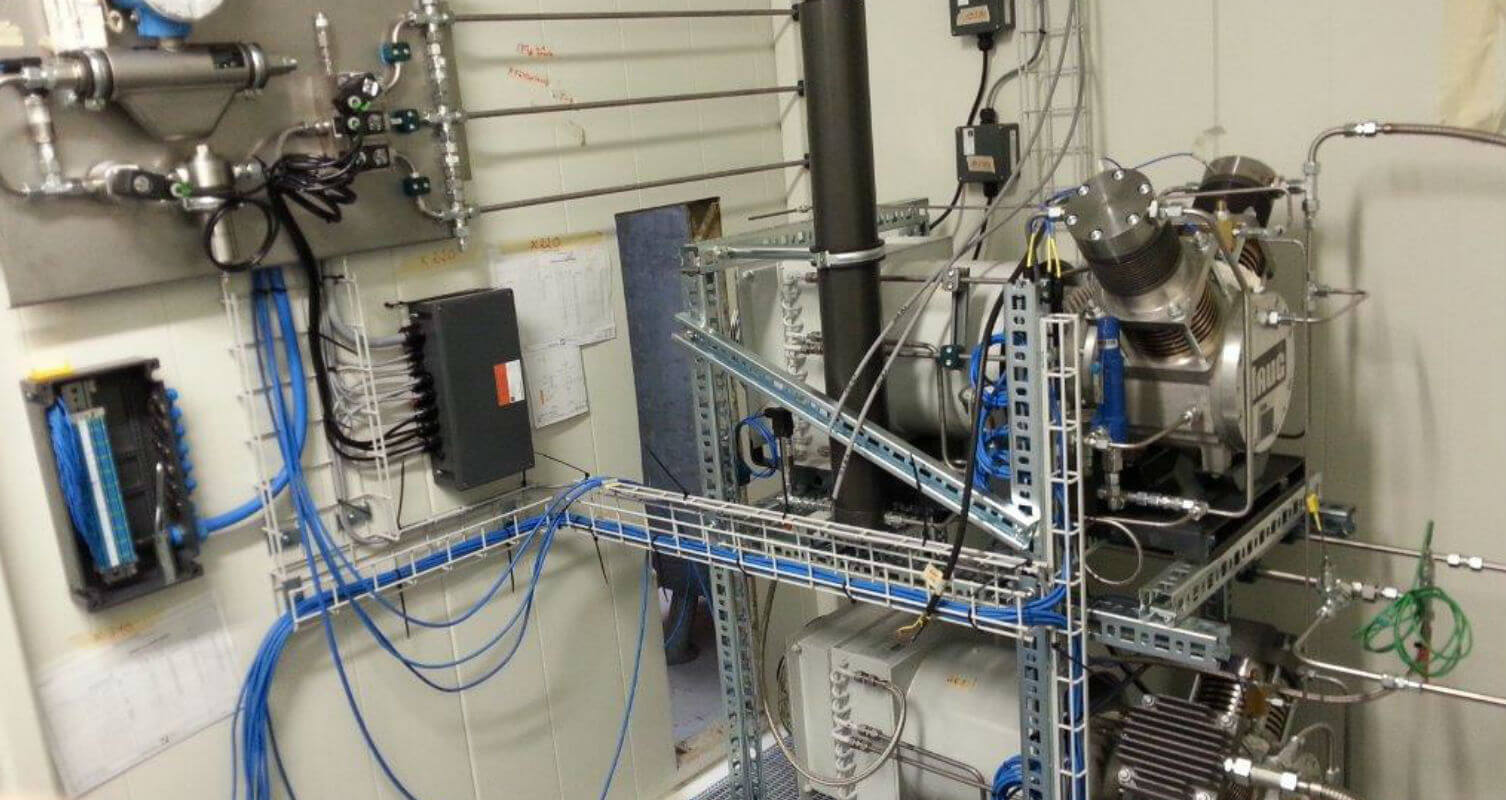

The entire treatment plant and compressors are built by the plant engineer in a container.

The compressors had to be oil-free and had to be designed for continuous operation. Demanded were reliable and maintenance-friendly compressors.

HAUG Sauer solution

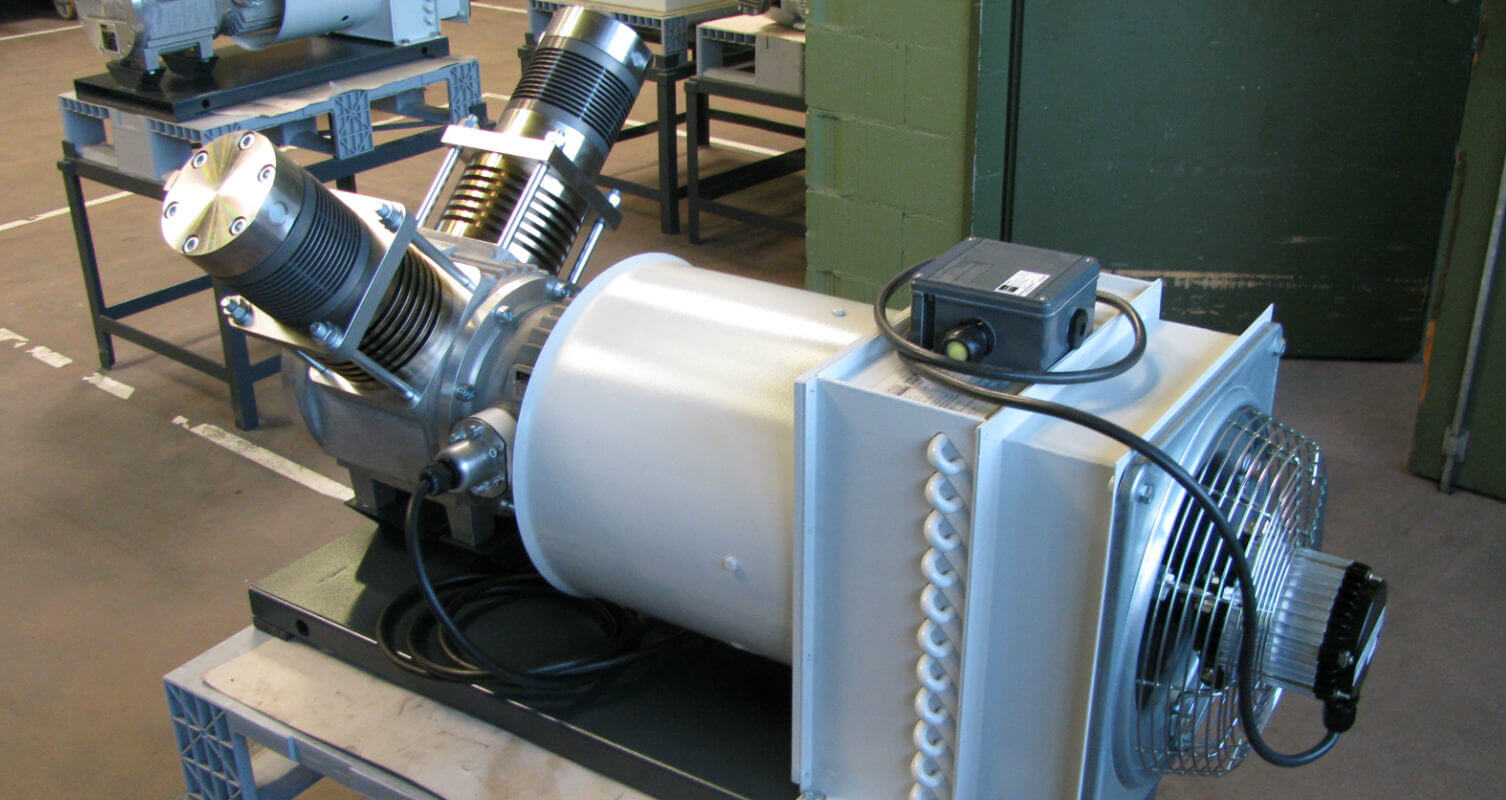

HAUG Sauer provided two 2-stage compressors of the Mercure type. In the first compressor, approx. 15 Nm3/h of biogas is compressed. After processing in a membrane a compression of about 10 Nm3/h of biomethane (with a methane content better than 96%) to a maximum of 300 bar takes place.

The key arguments for HAUG Sauer were: high reliability and easy maintenance, oil-free and gas-tightness, reciprocating compressors individually tailored to the customer, high flexibility of compressors regarding variable suction and discharge pressure.

Biogas as an environment-friendly energy source

Biogas is produced by the anaerobic fermentation of biomass, for example, residues from the food industry, waste, sewage sludge or renewable raw materials.

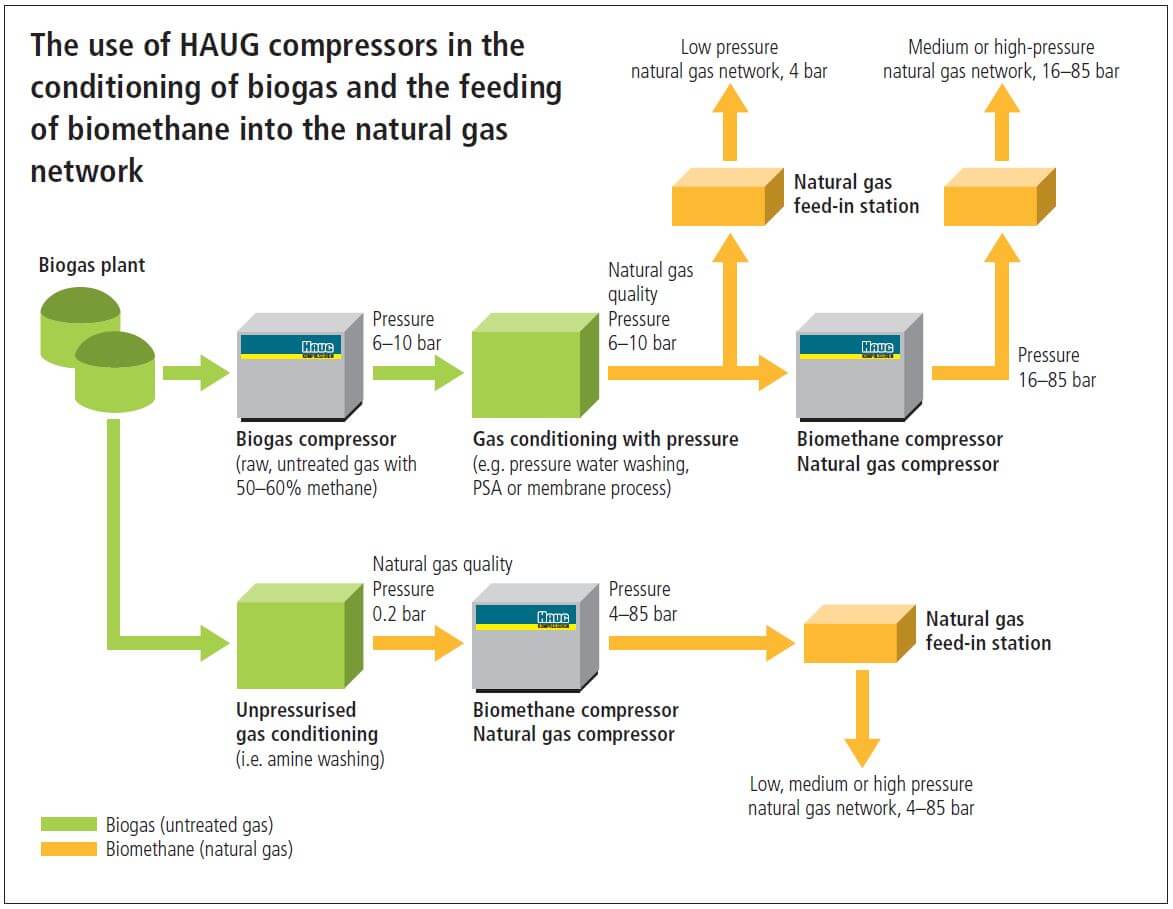

In fermentors, biogas is produced from biomass in anerober fermentation. Depending on the origin of the biomass varies the gas composition of the biogas. A typical gas composition is 60% CH4 (methane) and 40% of CO2 (carbon dioxide). The gas is wet (saturated with water) and contains contaminants such as H2S. Moisture and H2S are removed in the pre-cleaning.

In the fermenters and in the pre-cleaning usually low-pressure blowers are used. Compressors are needed when the biogas is to be stored or when the biogas is to be processed, so that the methane content is greater than 96%. The biogas upgrading can be done by different methods. Practically all require a process pressure from 6 to 15 bar, which is generated by compressors.

Examples of biogas / biomethane compressor applications

- Upgrading biogas to biomethane

- Supply into the natural gas network

- Supply for vehicle refueling

- Biogas vascular compression in the fermentation

- Biogas, biomethane and CO2 compression for storing surplus electric energy in the natural gas grid (power to gas)

Technical advantages of the HAUG compressors

HAUG piston compressors have the best conditions for many biogas and biomethane applications thanks to their oil-free, dry-running and gas-tight design.

- no gas pollution by oil

- technically sealed, in operation or when stopped

- flexible regarding variable suction and discharge pressure