Refrigerant gas or R-gas compressor

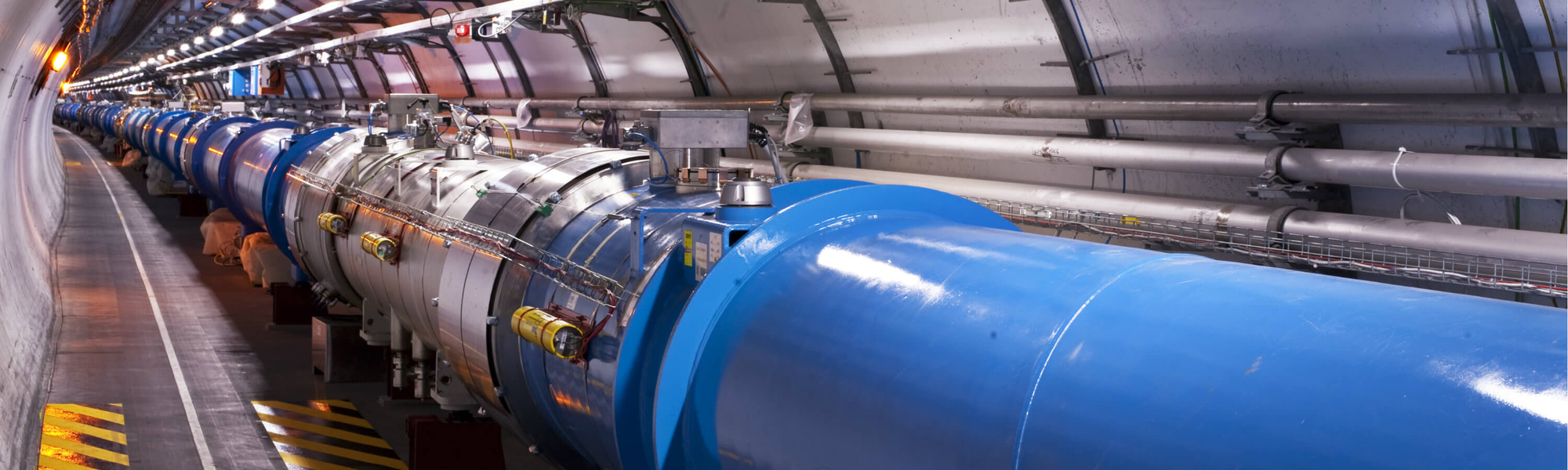

Refrigerant C3F8 circuit compressors for nuclear research at CERN in Geneva

Starting position / boundary conditions

The Inner Detector of ATLAS experiment at CERN needs to be cooled at -20°C. Seven HAUG compressors assure the compression of the perfluoropropane (C3F8) in the refrigeration circuit providing the cooling of the detector. More than 200 m far from the Haug compression station the fluid evaporates inside the detector structures to remove about 60 kW produced by the detector electronics.

In reference example our customer is CERN. HAUG maintains with the international research team and with the engineers a long partnership for compression of various specialty gases.

Requirements

The customer operates its cooling system with the gas C3F8. It is prescribed that permanently no gas can leak from the system. The plant will provide the amount of cooling gas in order to cover the needs.

The gas C3F8 is available at about 1.2 bar(abs) suction pressure available. The maximum discharge pressure is at 17 bar(abs).

The compressor is integrated by plant manufacturer and is controlled and monitored via a control system.

The compressors are oil-free and are designed for continuous operation. Demanded are reliable and maintenance-friendly compressors.

HAUG Sauer solution

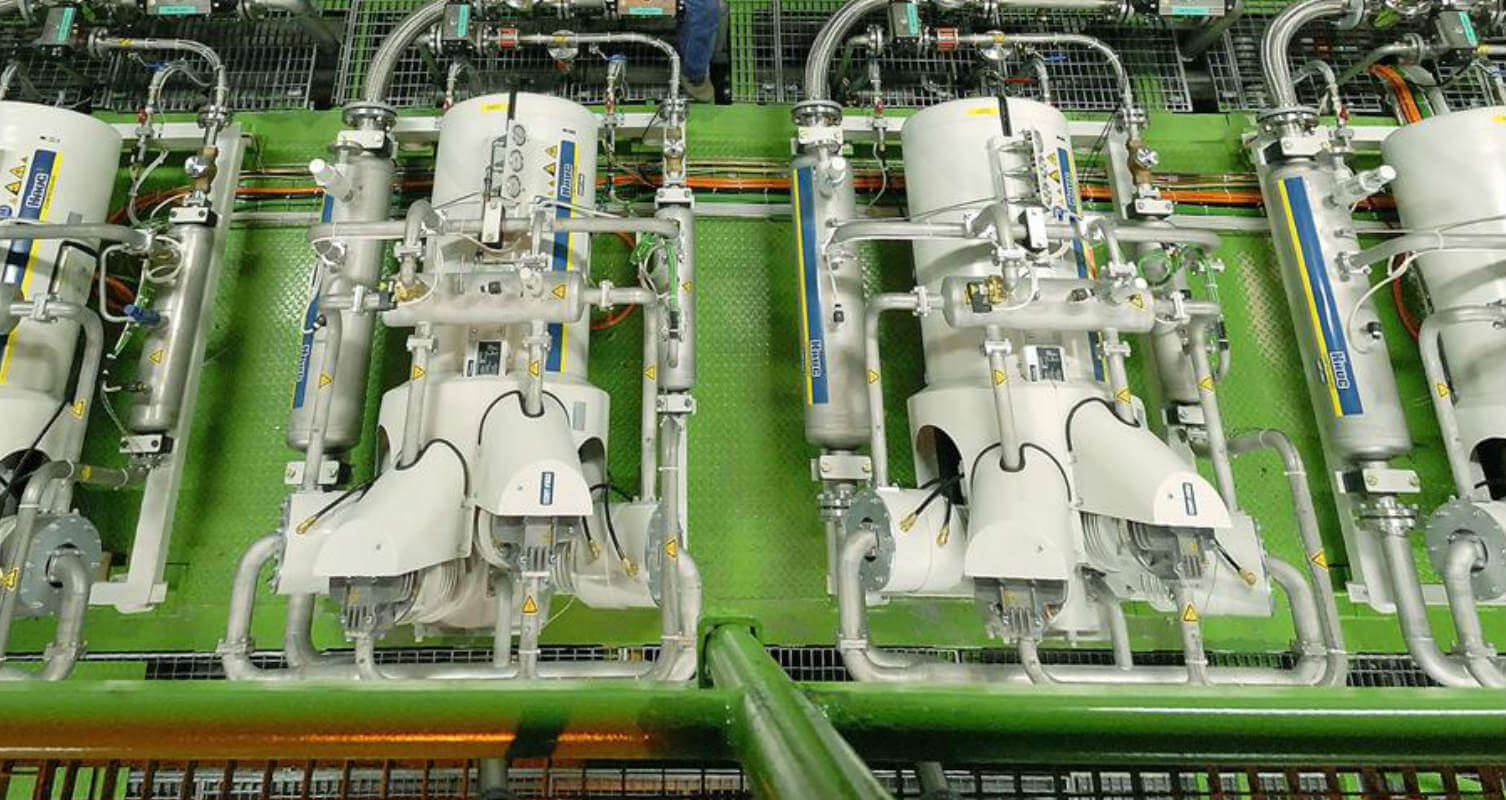

HAUG Sauer provided a total of 7 pieces of 2-stage compressors of Sirius type with a flow rate of approx. 100 Nm3/h. The scope of supply included the compressor with water and air cooling (combined).

The key arguments for HAUG Sauer were: high reliability and easy maintenance, oil-free, absolute gas tightness during operation or when stopped, personalized solution for the customer.

Oil-free compression of refrigerant gases

For certain processes with refrigerant, it is necessary or it has great advantages, if the compression is being made by oil-free compressors. Especially with new refrigerants based on gas mixtures containing hydrocarbons, the requirements on the refrigerant compressors have increased massively. Besides oil-free compression gas tightness is almost always required.

- Compression of ammonia

- Compression respectively recovery of R410 and gas mixtures made from R410

- Recovery of refrigerant gas by the maintenance of cooling and process systems (for example R134a)

Technical advantages of the HAUG compressors

HAUG piston compressors have the best prerequisite for refrigerant gas applications thanks to their oil-free, dry-running and gas-tight design.

- no gas pollution by oil

- technically sealed, in operation or when stopped

- flexible regarding variable suction and discharge