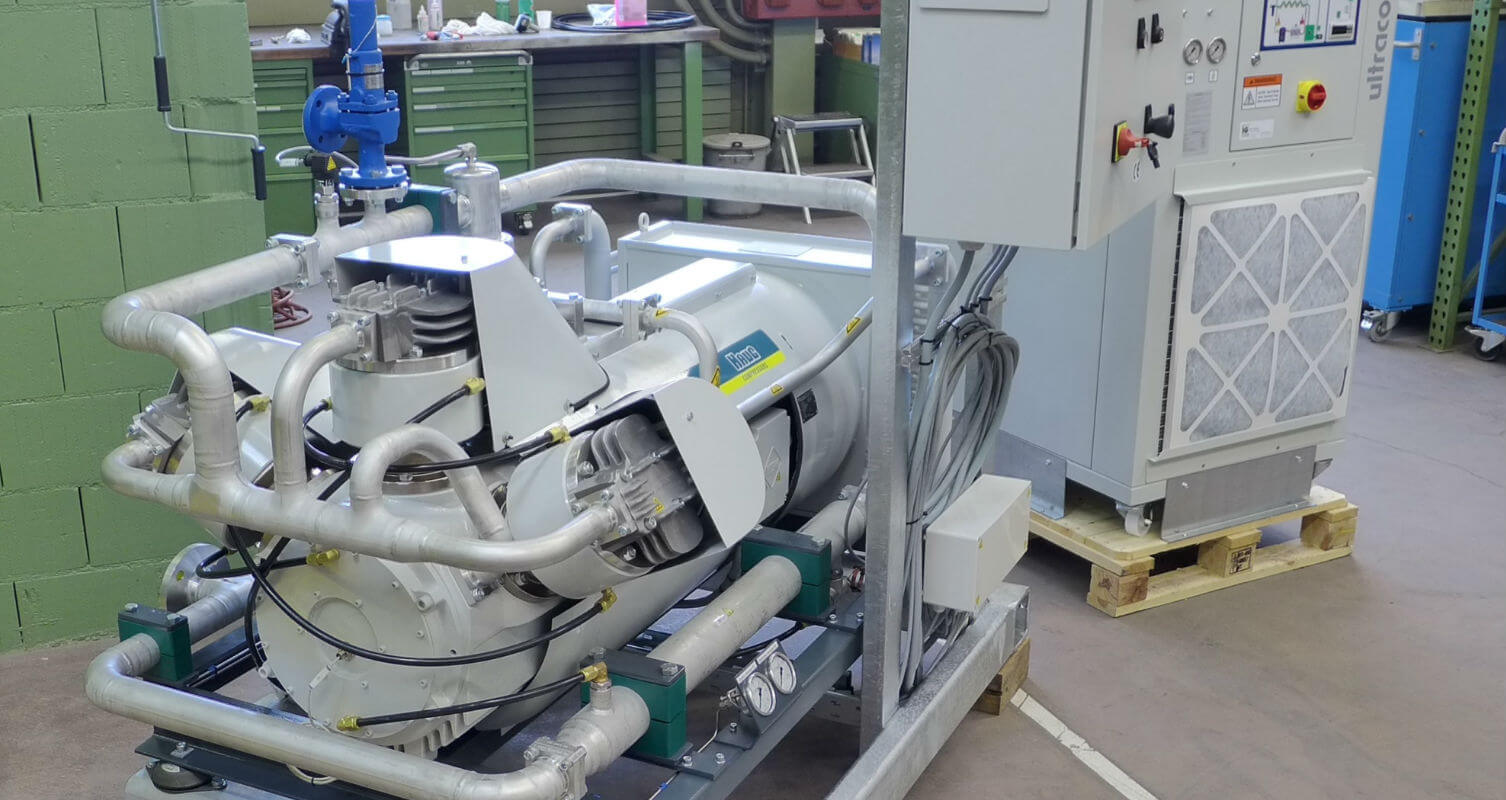

O2 - oxygen compressor

Oxygen booster to a PSA plant a gold mine in Africa

Starting position / boundary conditions

For the extraction of gold in gold mines, a method is applied, which requires oxygen as an oxidizing agent. Because these mines are located in remote areas, the operator must provide the entire infrastructure for the operation of the mine. For the supply of oxygen uses the operator a procedure to produce oxygen from air by pressure swing adsorption. Such plants are called short PSA or VPSA systems.

Oxygen is a highly reactive gas. Therefore a completely oil-free compression is an absolute "must". Few compressor manufacturers are capable to compress oxygen capable. HAUG Sauer built since the 80s compressors for oxygen in the power range 0.5 to 90 kW.

Our customers are on one hand one of the world's largest PSA plant manufacturers and on the other hand one of the world's largest gas distribution companies, which provide the gas to the mine.

Requirements

The suction pressure in this application is normally at 5 bar(abs) and the final pressure at 13 bar(abs). The required flow rate is from 150 to 300 Nm3/h.

The system must be designed for continuous operation and for high ambient temperatures of maximum 45°C. Demanded are very reliable and maintenance-friendly compressors.

HAUG Sauer Solution

The solution of HAUG Sauer includes a 1-stage compressing compressor from the series Sirius. The compressor operates oil-free and dry running and is equipped with the hermetic and contactless magnetic coupling. Depending on the flow rate has the compressor 2, 3 or 4 cylinders. The compressor is water cooled with a water-recirculation cooling system for autonomous operation. The package consists of the compressor control and water recooling system.

The key arguments for HAUG Sauer were: high reliability, great experience, oil-free, individually tailored compressor solution to the customer.

Oil-free compression of oxygen

Oxygen is one of the gases were oil-free compression is compulsory. It is also compulsory to clean the compressor so that it is "oil- and grease-free" before it is handed over for operation. This is due to the high flammability of oxygen. Oxygen is a strong oxidising agent. Contaminants, oil and grease can ignite in this environment, with the result that the compressor begins to burn. Special expertise is, therefore, required to produce oxygen compressors. HAUG has been building compressors for oxygen since the 1980s.

HAUG oxygen compressors are often used as boosters to an on-site gas production plant. Oxygen is generated using a PSA-, VPSA- or membrane system. Depending on the process, the pressure from the generation plant is either at atmospheric pressure (VPSA) or at around 4 bar (PSA). Depending on the application for which the oxygen is being used, the pressure may then need to be increased. This is achieved using a booster.

Oxygen applications in conjunction with an on-site gas generation plant include independent oxygen supply in hospitals or mobile clinics and oxygen supply in remote areas, e.g. for the extraction of raw materials such as gold or for metalworking.

Oil-free HAUG piston compressors for oxygen compression

HAUG compressors are ideally suitable for compressing oxygen thanks to its oil-free, dry-running and gas-tight design.

- no gas contamination by oil-free and dry running compression

- Safe operation by using specific, oxygen-compatible materials

- technically tight gas compressors in operation or when stopped