H2 - Hydrogen and synthesis gas compressor

Synthesis gas produced from biomass for alternative energy supply

Starting position / boundary conditions

Synthesis gas is being produced from biomass and then processed into hydrogen via an industrial process. The process is environmental-friendly and supplies alternative energy with synthesis gas and hydrogen.

In reference example, our client is an international research company in Austria. This is a pilot project with the participation of international plant manufacturer and power supply companies.

Requirements

The synthesis gas consisting of a mixture of hydrogen, CO and CO2 is produced in a reactor and is available at atmospheric suction pressure. The maximum discharge pressure is around 30 bar.

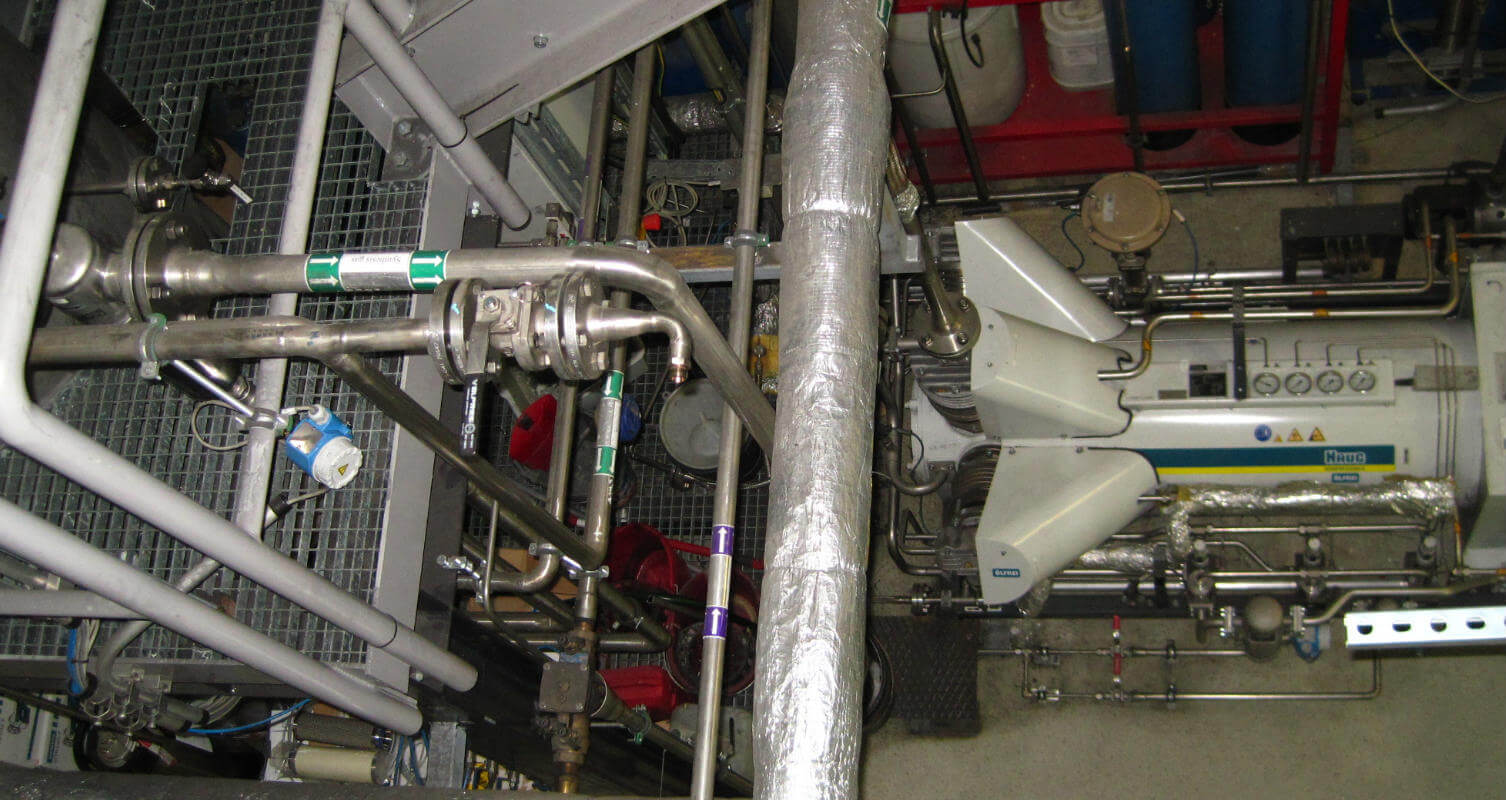

The compressor is integrated by plant manufacturer and controlled and monitored via a control system.

The compressors must be oil-free and must be designed for continuous operation. Demanded are reliable and maintenance-friendly compressors.

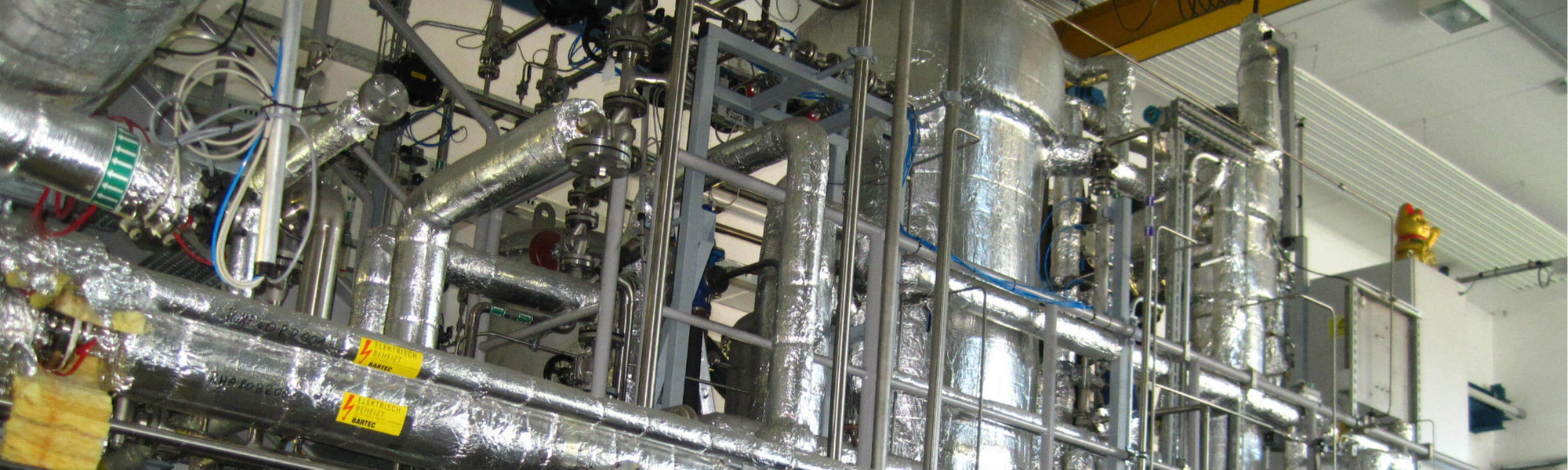

HAUG Sauer solution

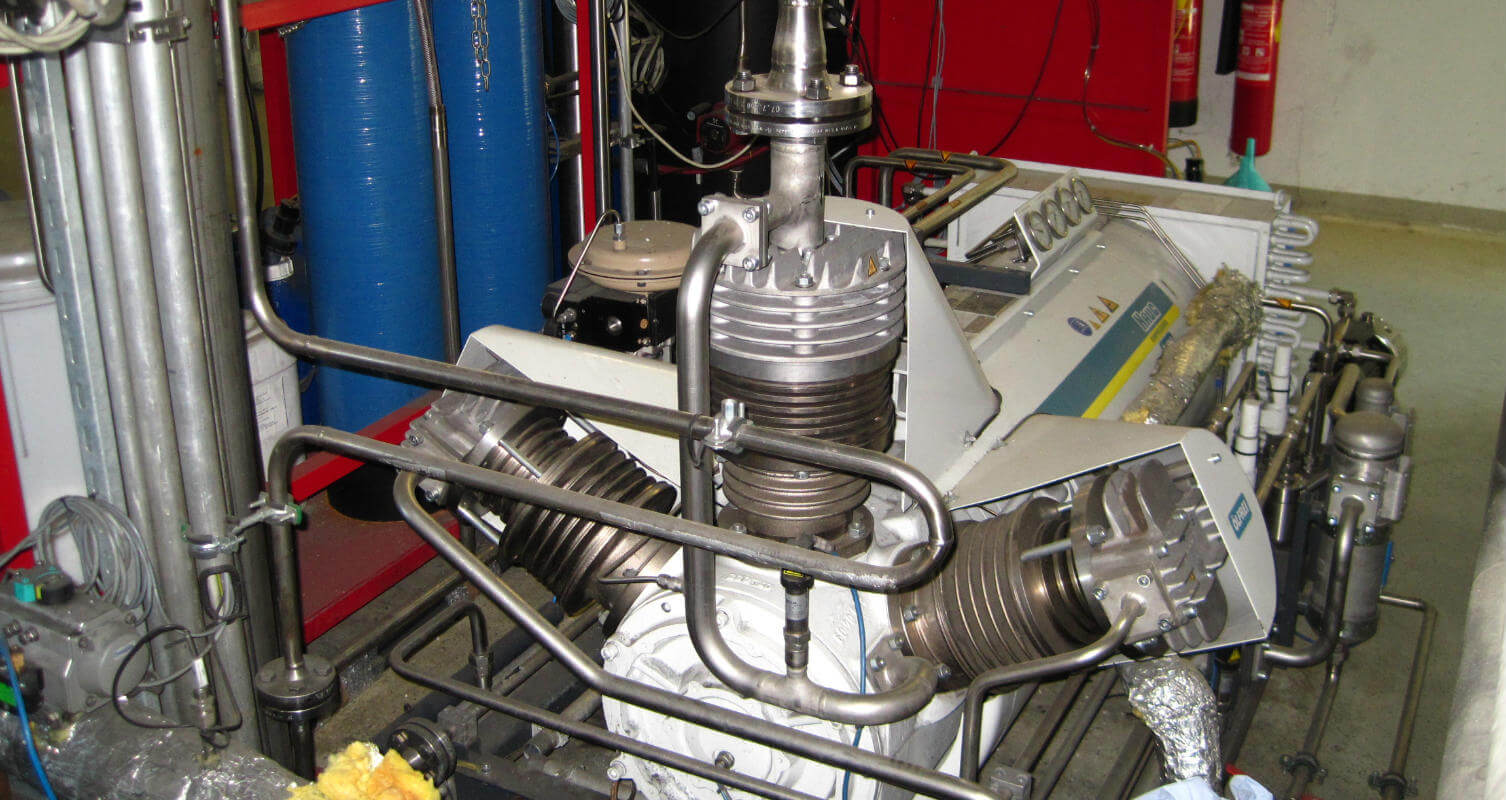

HAUG Sauer provided a 3-stage compressor type Sirius giving a flow rate of about 40 to 60 Nm3/h.

The key arguments for HAUG Sauer were: high reliability and easy maintenance, experience similar applications, oil-free and gas-tightness, reciprocating compressors individually tailored to the customer, high flexibility of compressors regarding variable suction and discharge pressure with different gases

Hydrogen applications in industry and as an environmental-friendly energy source

Hydrogen is an important gas for the industry and it is used in numerous applications:

- as cutting and welding gas in metalworking

- as protective gas and coolant in the semiconductor industry and in research

- in the food industry and in the preparation of the metal as a process gas in the production

Hydrogen is being used incerasingly also as energy carrier for reasons of environmental protection, because by the combustion of hydrogen only water is produced.

For example hydrogen may be produced from biomass via a synthesis gas. Hydrogen is mainly produced by electrolysis. Depending on the process, the hydrogen pressure is at atmospheric pressure up to about 30 bar. Compressors are compressing then to a final pressure where the gas is stored, for example, in the natural gas grid or in bundles of cylinders for vehicle refueling or for industry.

Technical advantages of the HAUG compressors

HAUG piston compressors have the best conditions for many hydrogen applications thanks to their oil-free, dry-running and gas-tight design.

- no gas pollution by oil

- technically sealed, in operation or when stopped

- flexible regarding variable suction and discharge pressure