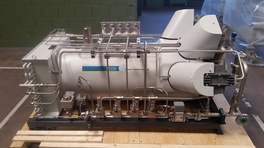

HAUG.Sirius NanoLoc - high pressure oil-free and gas-tight compressors (11 - 30 kW)

Unique combination of high-pressure cylinders with NanoLoc® design can reach a discharge pressure up to 451 bar(abs). At the same time the hermetically sealed and entirely wear-free drive with magnetic coupling ensures compression of various gases without leaks. This system ensures no gas losses to atmosphere and no compressed gas pollution from outside.

HAUG oil-free and gas-tight compressors are environmental friendly because there is no oil disposal and gas leakage which can contaminate the environment.

NanoLoc® Design

- Especially suitable for high pressures >101 bar(abs) because sealing without piston rings

- No friction losses in the cylinders due to friction-free sealing

- No wear at cylinders and very low wear of piston, thus significantly longer service life than with piston and packing rings

- Lower overall height and very compact and simple design with only a few parts Service-friendly, components are easy to replace

- Service-friendly, components are easy to replace

- No water cooling required

- Lower power consumption, since pistons move without friction in the cylinder

Features

- Completely oil-free

- Gas-tight design with magnetic coupling

- Compressor block leak rate <0.001 mbar l/s

- Air-cooled or water-cooled versions

- Motor power from 11 up to 30 kW

- Rotary speed range 970 up to 1450 rpm

- Suction pressure max. 31 bar(abs)

- Final discharge pressure max. 451 bar(abs)

- Modular cylinder configurations

- 4-stage compression

- Flow rate max. approx. 60 Nm3/h

- Explosion-proof compressor version (conform with ATEX zone 1 or zone 2)

- Very robust and long-last construction

- Compact and foundation-free installation

Applications

- Bottling of industrial gases like air, nitrogen, noble gases, hydrogen

- Storage of wind and solar energy (power to gas)

- Synthesis process gas compression for renewable energy storage

- Emergency gas storage at on-site gas generation systems

- Hydropower stations

- Hydrogen fuel stations

- Hydrogen storage at electrolysis plants

- Steel industry process gas

- Research and development applications … and many more