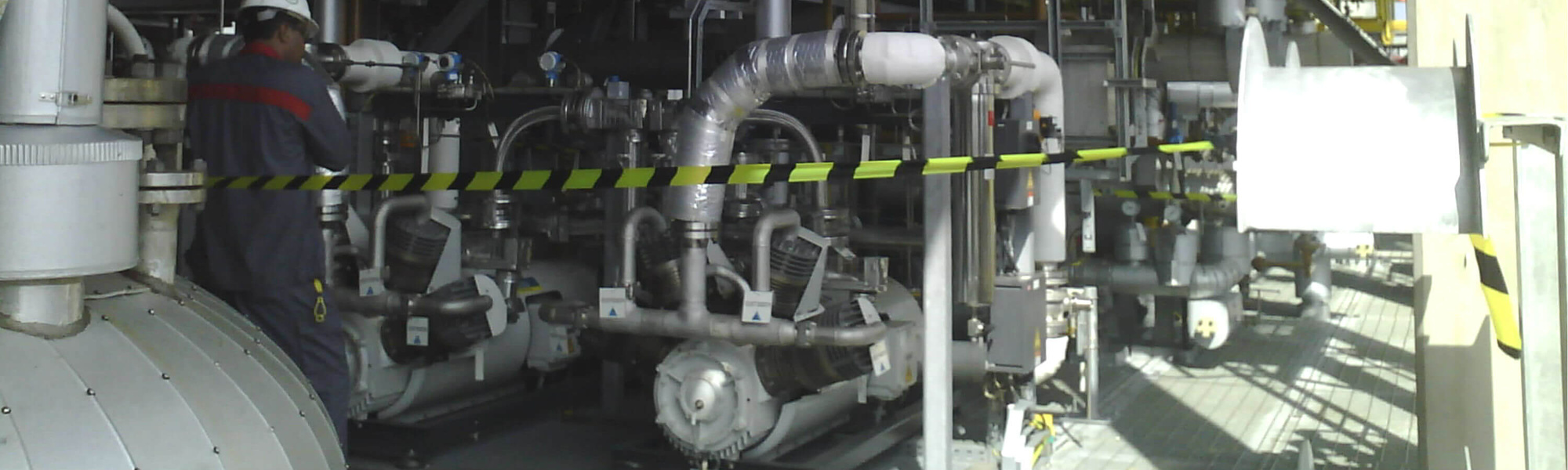

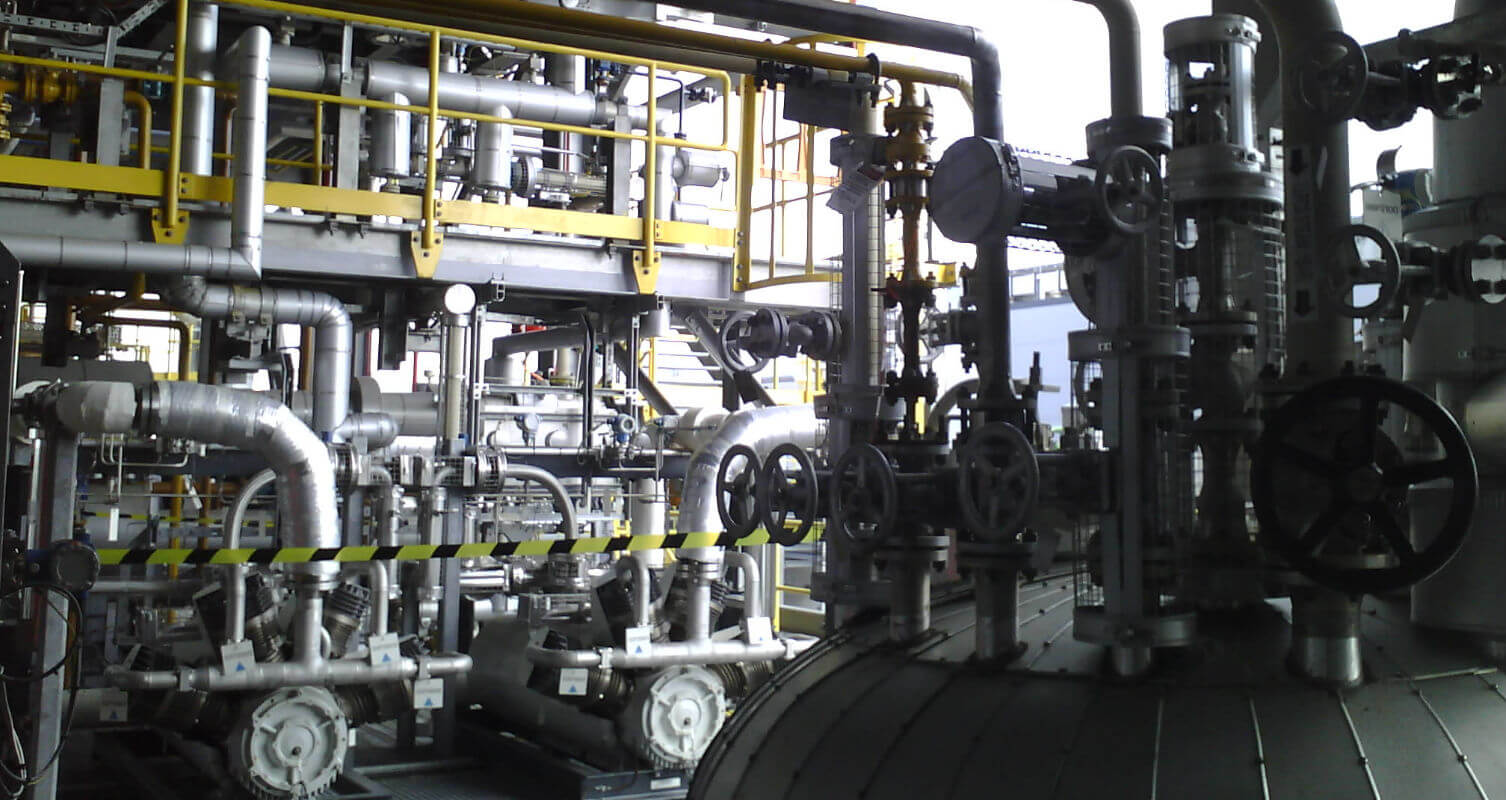

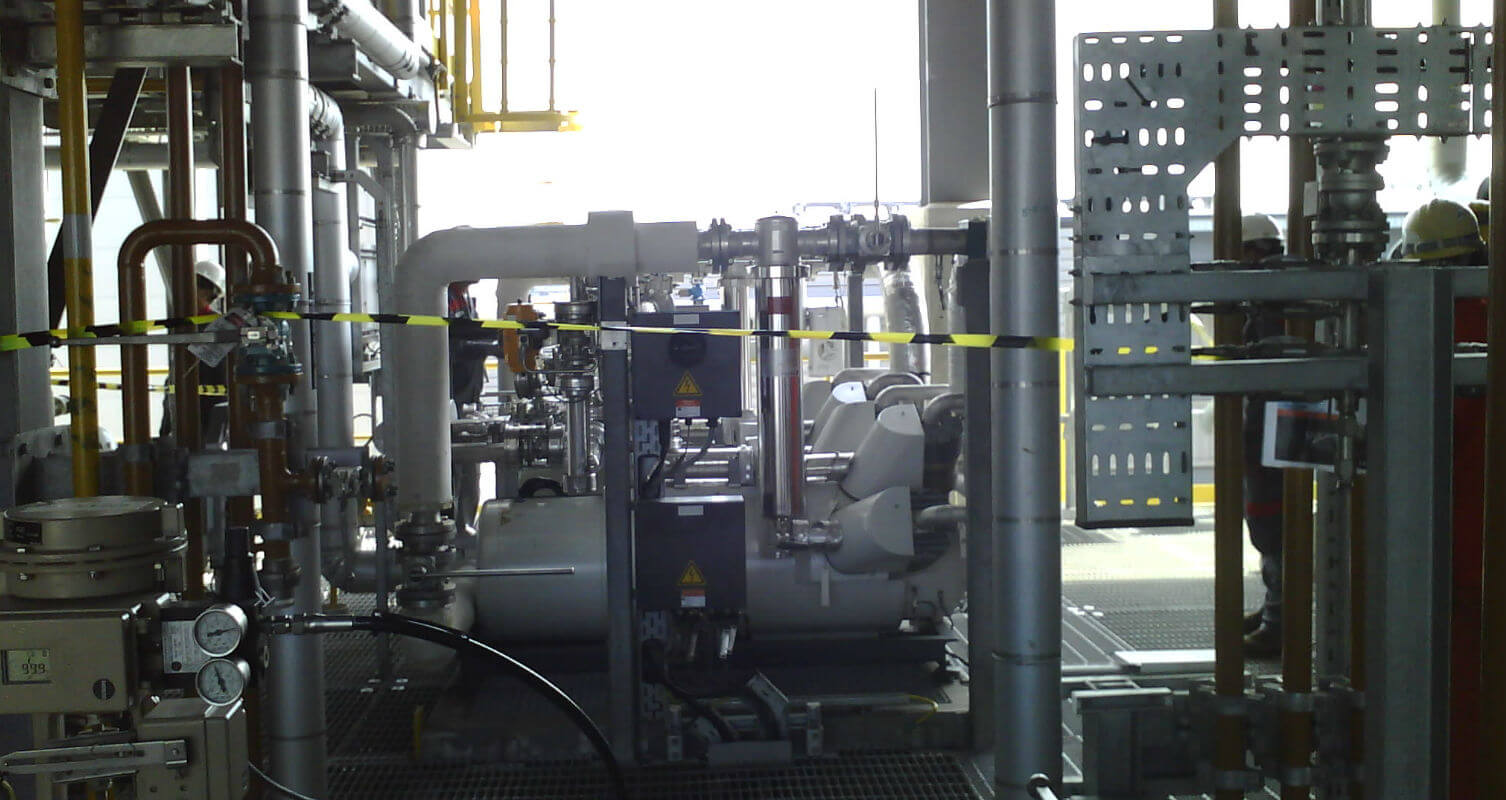

N2 - nitrogen compressor

Nitrogen booster in a chemical factory in Singapore

Starting position / boundary conditions

A global chemical company needs different process gas compressors in its newly built production plant for plastics in Singapore.

Available in the plant is nitrogen from an air separation plant with a network pressure of about 6 bar.

In the production process, nitrogen is needed at a pressure of 80 bar. Another application is the storage of nitrogen for inerting, which is used in case of failure for safe shutdown of the production plant.

Nitrogen contaminated with solvents falls in the production process. Compressors must compress the exhaust gases and thus recover a part of the exhaust gas and/or deliver the exhaust gas to a disposal facility.

Nitrogen is a very inert gas and is therefore used in many industrial processes as monitoring and protective gas. Oil-free compression is an absolute must in process technology.

Our customers are in one part the world's known gas supply companies on the other hand, industrial enterprises, which build the facilities directly or through a general contractor or engineering office.

Requirements

The suction pressure in the application in the production process is at 6 bar and the final pressure 80 bar. The requested flow rate are in the range of 100 Nm3/h.

For exhaust processing of nitrogen with solvent is sucked at atmospheric suction pressure and compressed to around 3 bar. The flow capacity of two compressors is at 500 Nm3/h.

The system must be designed for continuous operation. Demanded are very reliable and maintenance-friendly compressors.

HAUG Sauer solution

The solution of HAUG Sauer includes a 4-stage compressor and other two 1-stage compressors of the series Sirius. The compressors are oil-free and dry running and are equipped with the hermetic and contactless magnetic coupling.

The key arguments for HAUG Sauer were: high reliability, wide experience in the process industry, oil-free and gas-tightness, individually tailored to the customer compressor solutions.

Compressor applications with nitrogen

Nitrogen is a very popular inert gas, because it is cheap to produce and chemically very inert. Nitrogen, therefore, is happily used as a safety gas in industrial processes and process engineering.

Nitrogen is needed in the pharmaceutical industry for the coating of tablets. Under a protective nitrogen and solvent atmosphere, the tablets are coated in a closed spray-coating process. Spraying occurs via nozzles. This requires a compressor, which compresses the gas mixtures for the jets.

Nitrogen compressors are needed in the industry, where the existing nitrogen pressure is not sufficient, for example for use in laser cutting or for the purification of process filters with the product gas in the counter-current.