Core competencies

Highlights of HAUG oil-free piston compressors

- absolutely no oil in the whole compressor

- compressors are completely dry running

- oil-free compressors are suitable for processes and applications with high demands on gas purity and process quality

- oil-free compressors are also suitable for operation with long standstills, frequent operation interruptions and cold starts

- long service life of the components

Oil-free

50 years of experience with completely oil-free compressors

Where there are high demands on gas quality, oil-free compressors can reduce operating costs and significantly reduce risks, because gas treatment and filtration after the compressor is simple or, in some cases, not required at all. Oil-free compressors are therefore ideal for processes and applications which have high demands for the absence of oil and for gas purity.

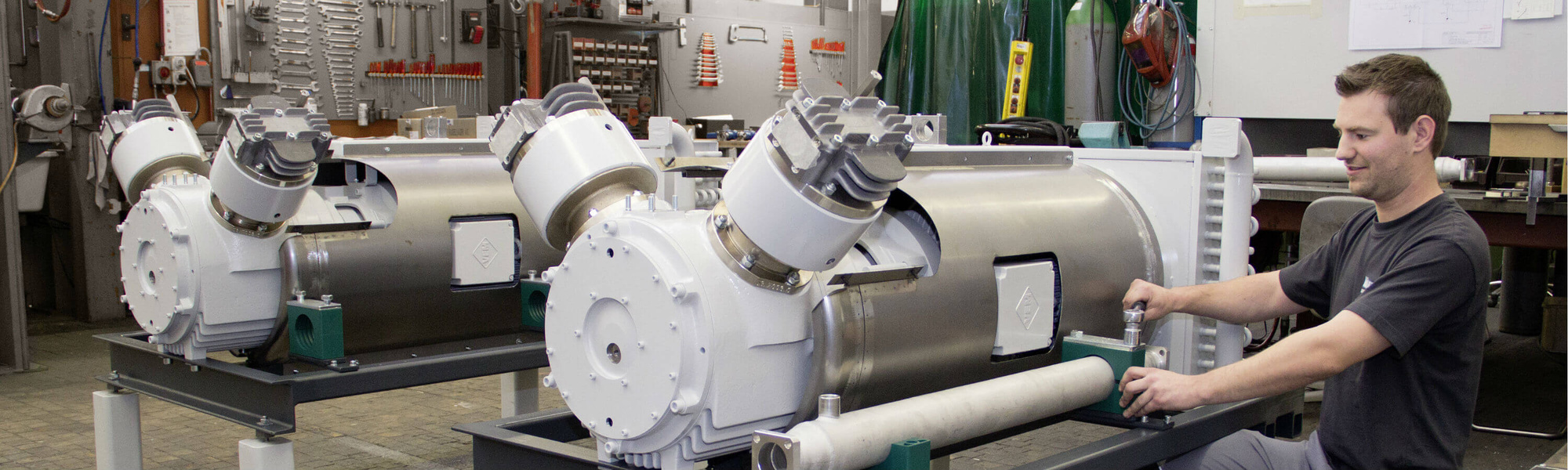

High-tech manufacture

Through the application of precise manufacturing techniques and the use of special high-grade materials, we produce highquality piston compressors with long lasting components. HAUG compressors are characterised by high operational reliability, in continuous operation as well as in intermittent operation with long downtimes and for cold starts.

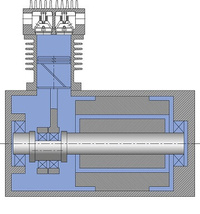

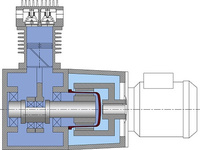

Gas-tight

Permanently technically gas-tight compressors in operation and at standstill

The risk of environmental contamination due to a gas leak is practically eliminated by gas-tight HAUG compressors. HAUG uses two systems to reach the hermetical gas-tightness:

- electric motor integrated in the crankcase

- system with magnetic coupling

Gas-tight even at high suction pressures

The compressors can be operated at maximum suction pressures of up to 10 to 20 bar (depending on the model and design).

Overload safety provided by the magnetic coupling

Another advantage of the design with magnetic coupling is the built-in “overload” protection. If the compressor is running with too high a load or discharge pressure, then the magnetic coupling “slips” and the compressor is safely shut down and stopped.

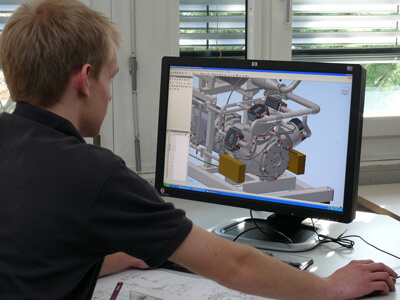

Consulting & Engineering

High quality and skills for the implementation of individual solutions

Through the skills of our employees and their many years of experience, we can implement individual customer solutions at the highest level.

A modular compressor system for cost-optimised series production and individual solutions

By altering the number and size of the cylinders, HAUG compressors can be very project-specifically designed and optimised. This also allows the energy efficiency of the compressors to be optimised.

High quality and competence in project implementation and manufacturing

The compressor block is manufactured at our own production plant in St. Gallen.

HAUG has modern and efficient machinery and long-term employees with high quality standards. Though our in-house manufacturing, we can also fulfil urgent orders quickly and cost-effectively.

Assembly and construction by qualified welders

Assembly and system integration of the compressors is carried out in our assembly and metalworking shops. Our welders work according to certified welding procedures. For oxygen compressors, special cleaning procedures are applied.

Every compressor receives an individual final inspection.

In the final inspection, the function, safety and operating data of each compressor is checked and documented.

Lean Management in production and logistics

The introduction of new management techniques ensures continuous and sustainable high quality, simplifies procedures and enhances customer benefits through improvements.