Special gases

Exhaust gas treatment of nitrogen with solvent

Starting position / boundary conditions

In production at Clariant in Basel arise as waste material a gas mixture of butane, toluene and nitrogen. In a gas separation plant butane and toluene are separated from nitrogen. The separation takes place with a pressure/condensation process.

Our customers were on one hand the operating company Clariant and on the other hand a German engineering company, which planned and built the plant.

Requirements

For exhaust gas treatment of nitrogen with butane/toluene is sucked at atmospheric suction pressure and compressed to around 3 bar. The flow rate of two compressors is 500 Nm3/h.

The system must be designed for continuous operation. Demanded are very reliable and maintenance-friendly compressors.

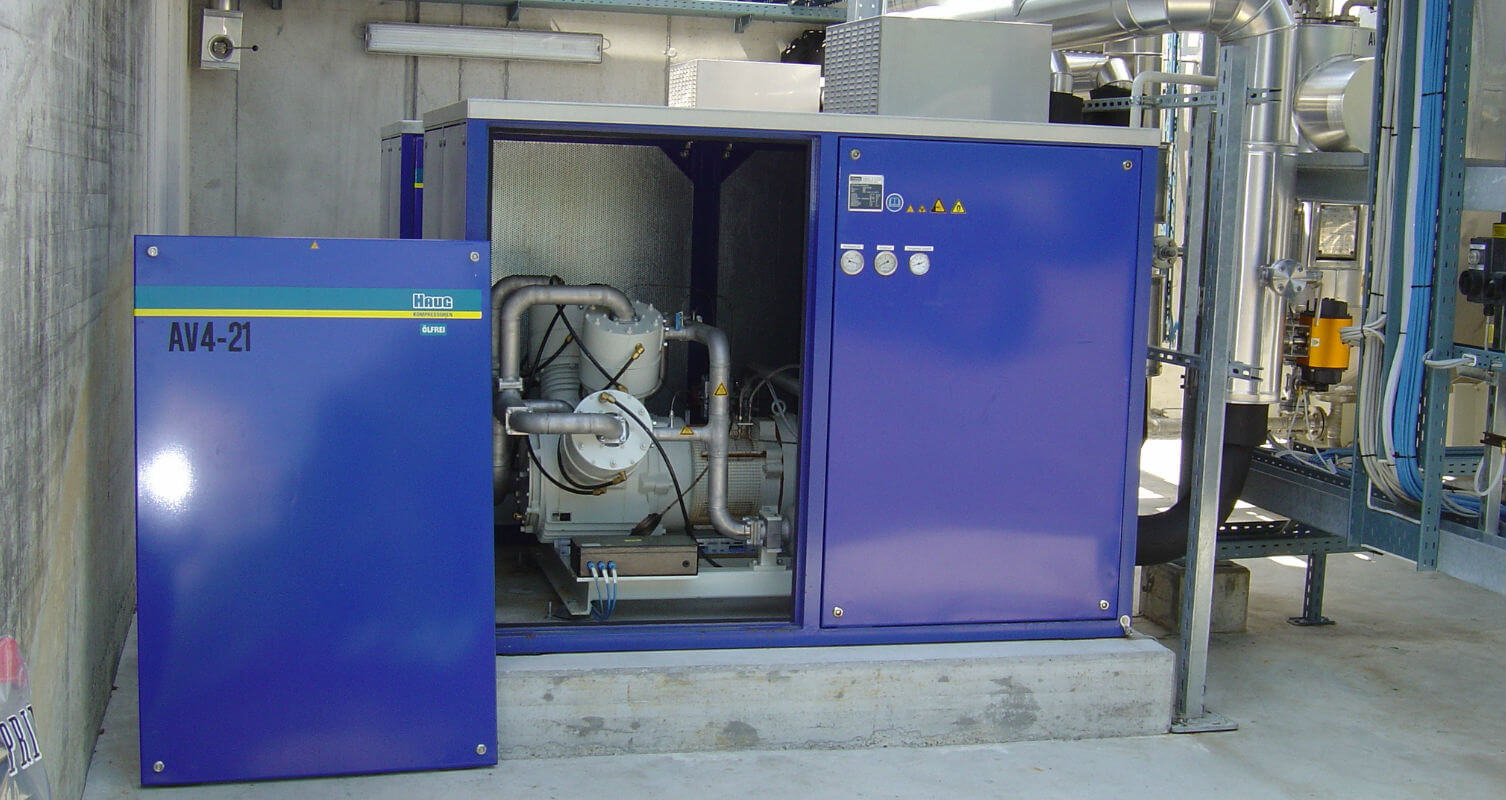

HAUG Sauer solution

The solution of HAUG Sauer included two 1-stage compressors of the Sirius series. The compressors are oil-free and dry running and are equipped with a hermetic and contactless magnetic coupling.

The key arguments for HAUG Sauer were: high reliability, wide experience in the process industry, oil-free and gas-tightness, compressor solutions individually tailored to the customer.

Compressor applications with special gases

The variety of special gas applications is large. Most applications come from the chemical industry and research. We have implemented numerous projects with institutes and universities around the world. Our customers include the following research institutions:

- CERN - Nuclear Research Geneva

- EMPA - Swiss Federal Material Testing.

- ETH Zurich

- Research Center Jülich

- Helmholtz Zentrum Geesthacht

- PSI - Paul Scherrer Institute

- SINTEF Norway

- ZSW - Center for Hydrogen

- The University of Cagliari